52ND ANNUAL CONFERENCE, Bali, Indonesia, 24-28 April 2013WP No. 156Quality Management Systems in ANSPs and the Relation with the SMSPresented by PLC |

Summary

The Intention of this paper is to show how QMS principles are transferred from theory to reality and how management and employees follow ‘prescribed’ procedures in order to reach a defined level of functioning. The relationship between SMS and QMS is considered, identifying differences and commonalities between those two management systems.

Introduction

1.1 Quality management has been established in many segments of the aviation system for a long time, especially by the airline operators. The first step was the implementation of quality control (QC) and quality assurance (QA). However, in 1990s many airlines introduced a formal quality management system according to ISO 9001:1994.

1.2 The ISO 9000 family of standards was developed by the International Organisation for Standardisation (ISO) to assist organisations of all types and sizes to implement and operate quality management systems (QMS). ISO 9001 specifies requirements for QMS where an organisation needs to demonstrate its ability to provide products or services that fulfil applicable requirements. QMS is customer oriented, with the concept of continuous improvement. The principle may be illustrated as a continuous circle, starting from customer requirements and expectations, and resulting in the 4 main elements of the organisation’s activities: Plan/ Do / Check /Act (which is a circle itself because after “Do”, again the same principle has to be performed).

1.3 QMS should ensure, inter alia:

- efficiency of the management,

- efficient development of the organization,

- customer satisfaction increase,

- continuous education,

- continuous compliance with the requirements,

- continuous improvement,

- accountability and responsibility,

- appropriate documentation and records.

Discussion

2.1 QMS in air navigation services and legal aspects

2.1.1 In Europe it was not mandatory to set up a quality management system in air navigation service providers until the common requirements regulation 2096/2005 (later superseded by 1035/2011). There was best practice in early 2000s to implement the QMS in providers on a voluntary basis in order to enhance business process and to increase the level of service. Most QMS systems were implemented and certified against the standard ISO 9001:2000 and later ISO 9001:2008.

2.1.2 According to the Regulation (EC) No 2096/2005 (superseded by 1035/2011), laying down common requirements for the provision of air navigation services (ANS) an ANSP shall have in place a quality management system which covers all air navigation services it provides.

2.1.3 The QMS has to:

- Define the quality policy in such a way as to meet the needs of different users as closely as possible;

- Set up a quality assurance programme that contains procedures designed to verify that all operations are being conducted in accordance with applicable requirements, standards and procedures;

- Provide evidence of the functioning of the quality system by means of manuals and monitoring documents;

- Appoint management representatives to monitor compliance with, and adequacy of, procedures to ensure safe and efficient operational practices;

- Perform reviews of the quality system in place and take remedial actions, as appropriate.

2.1.4 An EN ISO 9001 certificate (set of international standards developed by ISO and used by many organizations to implement an in‐house quality management system), issued by an appropriately accredited organisation, covering the air navigation services of the provider is considered as a sufficient means of compliance to the regulatory requirements.

Note: The latest paragraph says that if an ANSP is certified against ISO 9001, it is an acceptable way to comply with the regulation. Most European ANSPs are certified against ISO 9001:2008. However, other means of compliance may be recognised by relevant national supervisory bodies.

2.2 SMS in air navigation services and legal aspects

2.2.1 A safety management system (SMS) has been mandatory for ANSPs for a long time. Most ESARRs were issued in 2000, including ESARR 3 (SMS use by ATM providers). Although QMS was standardised by ISO in 1994 and ESARR 3 standardised SMS in July 2000 with a 3 year deadline to complete the implementation, it is interesting that many ANSPs started with SMS and then with QMS. This was mainly because of mandatory and non-mandatory provisions; ESARRs were mandatory for EUROCONTROL members, while ISO 9001, at that time, was not. Furthermore, the key issue in the provision of the air navigation service is safety of services, while quality of services, although very important, is of lower priority.

2.2.2 In discussions between safety managers and the senior management of certain ANSPs, there might be arguments about priorities, based on safety recommendations by the safety manager, others might insist on priorities regarding operational and technical issues or on financial aspects.

2.2.3 Air traffic control was implemented in order to maintain a safe, orderly and expeditious flow of traffic. The core priority of air traffic control and of all other supporting ANS is safety. It is written in the safety policies and/or in the quality/business policies of almost every ANSP and signed by the CEO. Therefore, the management commitment to safety and consequently for the safety management system as the main management /organisation’s tool to manage safety is of crucial importance.

2.2.4 There should be a reasonable balance between safety and other factors such as capacity/delays, environmental issues, cost efficiency etc. It is accepted that zero risk cannot be achieved; Risk management within the SMS means that risk should be at a tolerable level and managed accordingly.

2.2.5 All ESARRs have been recently transposed into relevant regulations. Only the reporting directive 2003/42 still exists. The revised document (now in the regulation form) is in very mature draft form and it is expected to be issued very soon (status 01-Feb-2013).

2.3 Relation between QMS and SMS

2.3.1 SMS and QMS share many commonalities. They both:

a) Have to be planned and managed;

b) Depend upon measurement and monitoring;

c)Involve most functions, processes and persons in the organization; and

d) Strive for continuous improvement.

2.3.2 Because SMS and QMS share many commonalities, there might be a tendency to assume that an organization that has established and operates a QMS does not need an SMS. In the same way that SMS and QMS share commonalities, there are important differences between both. Shortcomings in the effectiveness of QMS to achieve the overarching objective of managing the safety risks the organization must confront, is just one of them.

2.3.3 SMS differs from QMS in that:

a) SMS focuses on the safety, human and organizational aspects of an organization and is strictly regulated with many regulatory requirements;

b) QMS focuses on the services and processes of an organization (i.e. customer and stakeholders’ satisfaction, better organisational performance, etc.).

2.3.4 The ESARR 3 guidance document EAM 3 / GUI 4 – Mapping between ISO 9001:2000 and ESARR explains most of the differences and commonalities between QMS and SMS. Also a specific workshop took place in 2007 (EUROCONTROL SASI project) with discussion about the relationship of an SMS versus a QMS.

2.3.5 SMS can be illustrated as a narrower and deeper QMS. SMS is implemented in operational units and in management structures.

2.3.6 Recently the Performance Scheme regulation 691/2010 was issued (and later versions/amendments, with 4 Key Performance Areas (KPAs): the safety KPA which is mostly focused on SMS, is the first KPA, comprising currently of 3 key performance indicators (KPIs).

2.3.7 In every single European provider SMS has priority over QMS. Although quality management had been established in many segments of the aviation system for a long time, especially by the airline operators, the CEO of every European ANSP declares in the safety policy that safety has the highest priority over any other segment of business. Integration of all management systems into one management system (as given as an option in the regulation 1035/2011 -update of 2096/2005) has much pro and contra elements and it will take many discussions before integration is implemented.

2.3.8 Many ANSPs meet certain elements of integration (e.g. Croatia Control and AUSTROCONTROL) at least in the organisational structure of departments (joint Safety and Quality Dept., where the safety manager is also the Head of the S&Q Dept.) and in performing common safety surveys and quality audits (i.e. making only one integrated internal audit consisting of one survey plan in combination with common site visits and reports).

2.4 Application of QMS

A fully documented QMS will ensure that two important requirements are met:

- The customers’ requirements – confidence in the ability of the organisation to deliver the service consistently meeting their needs and expectations.

- The organisation’s requirements – both internally and externally, and at an optimum cost with efficient use of the available resources – materials, human, technology and information.

2.4.1 The application of quality principles to safety management processes helps to ensure that the requisite system wide safety measures have been taken to support the organisation in achieving its safety objectives. Quality management cannot by itself, as proposed by quality dogma- “Assure safety”. It is the integration of quality management principles and concepts into an SMS under the safety assurance component that assists an organisation in ensuring the necessary standardisation of processes to achieve the overarching objective of managing the safety risks the organisation must confront. Quality management principles include procedures for monitoring the performance of all aspects of an organization, including such elements as:

a) Design and documentation of procedures (e.g. SOPs);

b) Inspection and testing methods;

c) Monitoring of equipment and operations;

d) Internal and external audits;

e) Monitoring of corrective actions taken; and

f) Use of appropriate statistical analysis, when required.

2.4.2 With correct appliance of both systems in an ANSP, ATCOs can benefit by having the highest possible and reasonable safety standards. Through a quality management system ATCOs can be part of all the processes in the company. It creates awareness of responsibilities. It also provides ATCOs with the possibility to be trained at the highest possible level, both operationally and scientifically.

2.5 Examples of relation between QMS and SMS

2.5.1 Example from Australia (AIS‐AIMSG, THIRD MEETING, Montréal, 9 to 12 November 2010):

2.5.2 Australia has been developing Civil Aviation Safety Regulation (CASR) Part 175 regulating the provision of AIS. A project has been underway since 2008 and currently instructions have been submitted to the Attorney General’s Department for legal drafting. Much consideration was given to the relative merits of an SMS over a QMS and vice versa during development of Part 175. Australia’s safety philosophy is based on risk management and therefore a SMS is the basis of the safety framework for both the CASA (regulator) and Air Services Australia (service provider).

2.5.3 The SMS is the overarching system by which an organisation manages safety and describes the processes to identify risks and mitigate the factors causing these risks. A QMS is but one means of demonstrating that quality procedures exist for the way data is processed. A QMS can be an integral part of a SMS. A QMS on its own though cannot guarantee that an organisation has a system in place to identify and eliminate safety risks involved in the collection, processing and publication of aeronautical data. In order to ensure that the QMS is relevant to the processing of aeronautical data the QMS provisions in Part 175 have been made more relevant so as to include the quality management requirements contained in RTCA/DO- 200A/EUROCAE ED-76.

2.6 The application of quality management principles to safety management processes

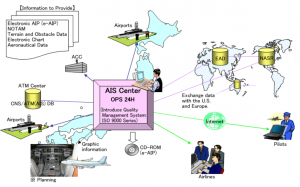

The example AIS:

Conclusions

3.1 SMS focuses on the safety aspects of the organisation. Safety is of ultimate importance and there is no compromise with safety: the minimum is an acceptable level of safety.

3.2 QMS focuses on the services and performance of the organisation and is oriented to stakeholders and customers.

3.3 While QMS focuses on conformity, SMS focuses on hazards.

3.4 Both non-conformities (according ISO 9000: “non-fulfillment of a requirement”, e.g. regarding the standard) and hazards can impact safety: hazards are closer to the sharp-end, i.e. closer to air traffic services and to aircraft operations.

3.5 Both systems enhance the management of the organisation and are essential and complementary management tools.

3.6 It is very hard or almost impossible to have an effective SMS without applying quality management principles.

Recommendations

4.1 It is recommended that this paper is taken as information.

References

ICAO Doc 9859 Safety Management Manual (SMM).

Quality Management Systems by DTI/UK.

ICAO AIS-AIMSG, third meeting/minutes.

EAM3/ICAO.

ATM Safety Management Interface between ANSP and NAA/NSA, EUROCONTROL.

UK CAA, QMS Guidance for Organisations providing ATS and/or CNS.

EC Regulation No 2096/2005.

https://www.mlit.go.jp/koku/15_hf_000110.html

QMS-QMM, Croatia Control Ltd.

Appendix 1 – Quality Policy Examples

Example of MATS common quality & safety policy

Malta Air Traffic Services Ltd. (MATS), the designated ANSP responsible for the Malta Flight Information Region, is fully committed in providing a safe, high quality and efficient service to world‐class standards in accordance with international standards and regulations.

MATS aims to continuously satisfy its customers, anticipating and embracing any change requirements in order to develop and implement strategies to meet change and produce results.

MATS consider Safety and Quality as its primary targets and consequently they are accorded the HIGHEST priority over commercial, financial, operational and social pressures and constraints (Francis Bezzina, Coordinator Safety and Quality, Malta Air Traffic Services).

Example of Croatia control Ltd Quality Policy

Croatia Control Ltd strives to achieve and maintain exceptional performance.

The prime quality of our services reflects our values and views demonstrated in daily business and procedures.

Quality arises in all business segments, in all phases of the working process and in all procedures associated with service provision, as well as at each working position.

A minimum level of quality implies meeting the requirements of ISO 9001:2008. The highest level of quality and its improvement are reached by permanent control, application of corrective measures, implementation of preventive measures including life‐long education of our employees, and by use of state‐of‐ the‐art technology.

The quality targets will be achieved by our motivated and competent experts, following the experience of air navigation service providers in Europe and all over the world, as well as providing services to the satisfaction of our customers and stakeholders.

Special consideration is given to human resources management, with a training system geared to international and national standards.

The quality of our services is ensured by the certified quality management system, periodically reviewed and assessed by the management continuously being improved, which is outlined in the Quality Manual and in supporting documents. Quality arises and is implemented at each working position, and all employees have to take part in its actualization.